Are you debating getting a smaller 3D printer to save some money? I made that choice nearly two years ago, and I’m just now recovering from it. Here’s my first-hand experience advice on how to make sure you don’t repeat my mistake and buy the wrong size 3D printer.

The size of your 3D printer (mostly) determines what you can print

It’s just easier to print smaller things on bigger printers, instead of bigger things on smaller printers.

When it comes to 3D printers, size is almost everything. The first 3D printers I owned were 256x256x256mm, but they were the older Ender 3 v2-style printers. Eventually, I sold those printers and upgraded to the Bambu Lab A1 mini, which offers a smaller 180x180x180mm build volume. I didn’t think that would be limiting at first, but it definitely was.

I’d estimate that most people who own printers have a model that’s 256x256x256mm or larger. The smaller 3D printers make up a very small portion of the market. Since the majority of 3D printer owners (and therefore 3D model designers) use the larger printers, most 3D print models are actually built for the larger machines.

This means that you could find a model that you really like, only to load it into your slicer and realize there’s no good way for you to print it. I’ve found models before that I thought would fit on my A1 mini, only to find it was just a few millimeters too large in one direction, meaning I couldn’t print the design as-is.

Smaller printers are cheaper if you can work around the size constraints

There are workarounds, but they’re never fun.

Credit: Patrick Campanale / How-To Geek

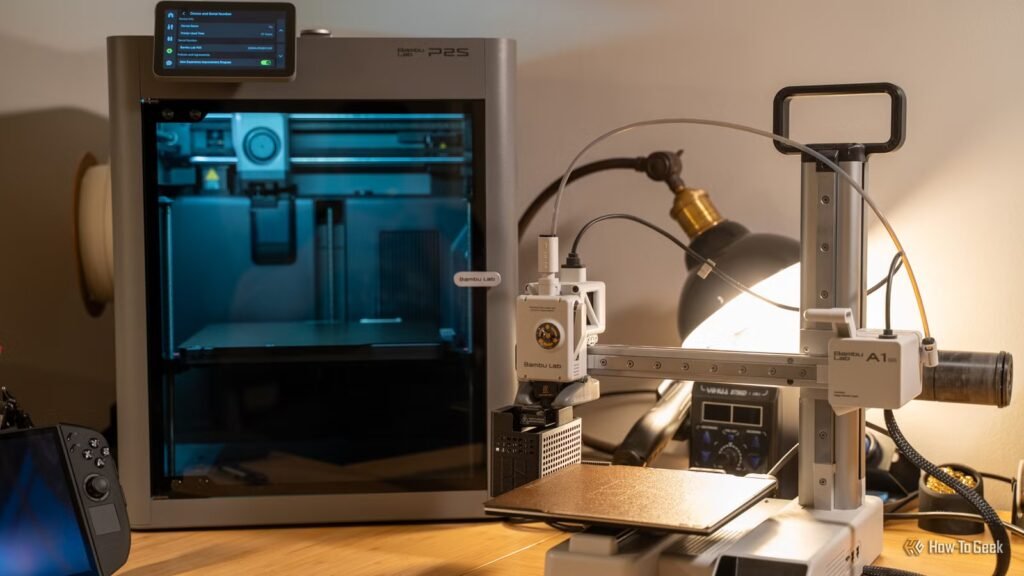

The reason I purchased the A1 mini in the first place was to save money. It’s a few hundred dollars less than most other models, while offering some pretty impressive specs and capabilities. I just didn’t fully think through how limited my smaller 3D printer would be. In fact, these limitations would eventually push me to sell the A1 mini and upgrade to a Bambu Lab P2S (now with a P1S sitting next to it).

I mostly got along with the smaller build volume, either by finding models that fit the build volume or just designing my own items. There’s another option if you have a smaller printer and the structural integrity of a print isn’t a huge deal: splitting a model.

Credit: Patrick Campanale / How-To Geek

In most modern slicer software programs, you can choose to split a model with a dovetail. This makes a sliding joint that you can use to join the two split halves of a model. Splitting a model is a great way to make something larger fit in a smaller build volume.

If the model you’re trying to print is 200mm long, but only 80mm wide and 50mm tall (like a small monitor shelf), then splitting the model in half allows you to easily print it on a smaller machine like the A1 mini.

Once printed, you simply slide the dovetails together and use some glue or a plastic welding soldering iron to join the two pieces. This method typically produces a fairly stable part, but I wouldn’t want to trust this for anything that’s going to be under a lot of stress.

When in doubt, go with a mid-size printer

Go big or go home.

Credit: Patrick Campanale / How-To Geek

Unsure of what size printer you need? The safest bet is to just go with a 256x256x256 system and call it a day. However, you could also download several models that you’re interested in printing and see what size machine they fit on. Bambu Studio, Orca Slicer, and Prusa Slicer are all free to download.

These slicers will let you load up different machine presets in them and show you both how long a print will take on that machine and whether a print would even fit.

Unless you’re working on the tightest of budgets or size constraints, I wouldn’t recommend going with a smaller 3D printer. They’re nice and cheap, but they’re just so much more limited than larger machines.

Credit: Patrick Campanale / How-To Geek

The crazy part is, my Bambu Lab P1S and P2S 3D printers don’t take up any more space (horizontally) than my A1 mini did. In fact, they take up less space because of the Core-XY nature of the printers.

Going with a machine that has a 256x256x256 build volume (like the Prusa CORE One+, Bambu Lab P2S, or Bambu Lab A1) just opens up so many doors in the 3D printing space, from printing more individual objects to simply larger projects.

You’ll find larger machines out there, like Bambu Lab’s H-series of 3D printer, the Prusa CORE One L and Prusa XL, or the Creality K2 Plus, but they can all get pretty expensive (and take up a good amount of space in your office).

Build Volume

256x256x256mm

Printing Speed

600mm/s

The Bambu Labs P2S 3D printer is ready to go out of the box and can have you printing within 15 minutes. It features up to 20-color printing with the AMS unit, has an upgraded built-in camera for remote monitoring and time lapses, and has an enclosed body for printing even high-temperature filament.

Which size you choose when it comes to a 3D printer can make or break the experience. I became pretty annoyed with having to work around the size limitations of my Bambu Lab A1 mini, and it eventually drove me to spend more money on a larger printer, when I would have saved money overall by picking up a larger machine from the start.

Don’t make the same mistake I did and buy too small a printer up front. Take the time to figure out what you want to print, and let that determine what size printer you buy.